1900 kVA MITSUBISHI S16R-PTA, STAMFORD S7L1D-E, 60hz 3phase Diesel Generator Set - E MH ST 2000/6/22-44

PDF

Diesel Generator Sets

Emergency Standby Power: Emergency standby power, provided by diesel generators, acts as a backup during power outages. These generators kick in swiftly during emergencies, ensuring continuity for critical operations. Ideal for homes, businesses, and industries, their usage duration should be limited to prevent wear. Strict standards like NFPA 110 ensure their reliability.

Prime Rated Power: Prime rated power generators serve as primary power sources, especially in remote locations. These diesel generators handle varying loads over extended periods, making them perfect for sites without grid access. Commonly mobile, they're crucial for mining, construction, and energy industries, offering consistent, prime-rated power supply.

Continuous Operation Power: Continuous operation generators offer non-stop, stable power output, especially where grid access is inconsistent or expensive. These generators operate at a consistent 100% load, making them indispensable for remote mining, military, or farming sites. Unlike prime-rated generators, they don’t vary in power, ensuring unwavering power delivery.

QUALITY STANDARDS

Our generators are manufactured in compliance with VDE 0530, BSE 4999 BS5000, IEC 34, EN12601; EN60204-1; TS ISO 8528-1 … -13; EN12100-1; EN12100-2; EN61000-6-4; EN61000-6-2; EN61000-4-11; EN61000-4-6; EN61000-4-5; EN61000-4-2; EN55011; EN55016-2-1; EN55016-2-3; EN61000-3-2; EN61000-3-3; EN55014-1; EN61000-6-2; EN61000-4-3; EN61000-4-4; EN61000-4-8; EN61000-4-11; TS EN ISO 3744; TS EN ISO 3746; TS EN 60034-1; TS EN 60034-22; TS EN ISO 3046; BS 5514; NEMA MG 21; IEC 60034, BS 4999/5000 and TS EN 60947-1..4 standards.

We have ISO 9001-2015, ISO 14001-2015, ISO 45001-2018 and ISO 1002-2006 management system certificates from Kiwa, an accredited independent quality organization.

Our generators up to 400 kw are manufactured in compliance with 2000/14/EC European noise emission directive and certified from Ente Certificazione Macchine.

We also have TS ISO 8528-4, TS ISO 8528-5, TS EN 13501-1+A1:2013 flame retardancy and TTS EN ISO 9227 certificates against anti-corrosion together with CE Declaration.

Engine Specifications

- MITSUBISHI series heavy duty diesel engine

- 4 CYCLE, WATER COOLING SYSTEM, TURBOCHARGED - AFTERCOOLER INDUCTION

- Electronic governor system

- 12/24 volt self-starter and charger alternator

- Changeable air, fuel and oil filter

- Flexible fuel pipe

- Oil discharge valve and extention pipe

- Industrial type silencer, exhaust spiral or compensator

- Maintenance free battery

- Engine block water heater (in automatic models)

- Diesel gen-set maintenance and operating instructions and electrical circuit diagram

Alternator Specifications

- Brushless, single bearing, flexible disc 4 poles alternator for harmonic failure

- H type isolation class

- IP 21-23 protection class

- Self exciter

- Electronic automatic voltage regulator

- Stator 2/3 step for harmonic failure

- The alternator windings are protected by insulating varnish against oil and acid

Genset Controllers

Datakom SMART 500-MK2

The SMART 500-MK2 is a cost effective genset controller ready for BMS integration and internet monitoring

OPTIONAL GENSET CONTROLLERS OPTIONAL

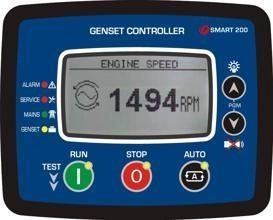

Datakom SMART 200

Datakom D500

Datakom D500-GSM

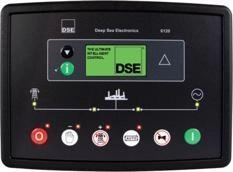

DEEPSEA 6120

DEEPSEA 7320

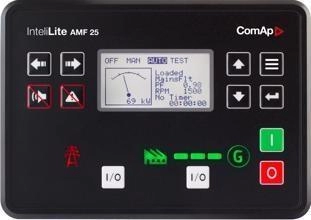

ComAp AMF25

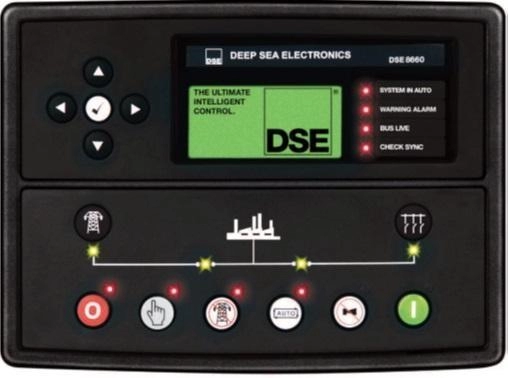

GENSET CONTROLLERS FOR SYNCHRONIZATION SYSTEMS OPTIONAL

Next generation synchronizing genset controller capable of every communication and functionality.

DEEPSEA 8610

DEEPSEA 8620

DEEPSEA 8660

ComAp InteliGen BaseBox

ComAp InteliGen 200

Container

- Chassis parts and load-bearing construction are manufactured from 140mm NPU

- The base metal sheet is manufactured from 2/3 diamond-shaped metal sheet

- Sidewall metal sheets are manufactured from 1.5mm ST 37 DKP trapezoidal metal sheet

- The top metal sheet will be manufactured from 1.5mm ST 37 DKP trapezoidal metal sheet

- Air disposing and suction parts are manufactured with the normal shutter in bolt-mounted hot-plug

- Lifting lugs are manufactured to bear the total load of the container (with generator)(8 pcs ISO Locked)

- PPG RAL 9010 paint application is followed for painting

- Internal illumination has 2x1x18 Watt waterproof fixture and 1x1x16 A monophasic plug fitting

- Top wall isolation is 0.8mm galvanised perforated metal sheet coating on 8cm fibro-glass glass wool plate

- The double-winged main door is manufactured with a pipe-type locking mechanism

- Service doors are manufactured with 4 single-winged and internal panic bar mechanisms to be locked outside (These doors are designed mounted inside the container body and doorknobs do not exceed container body

- Emergency stop button on long edges

- Warning signs are placed to necessary places inside and outside the container

(W x L x H) mm

External type

(W x L x H) mm

External type

SILENCER OPTIONS

- Standard industrial type

- Critical type

- Hospital type

CONTAINER OPTIONS

- Standard container

- Acoustic container

GEN-SET SAFETY PROTECTION & ALARMS

- High water temperature

- Low oil pressure

- High & low engine speed

- Low radiator water level

- Over current load

- High & low genset voltage

- Start/stop failure

OPTIONAL EQUIPMENTS

- Charge ammeter

- Moulded case circuit braker (in automatic models)

- Hospital/Critical type silencer

- Modular type sound-proof canopy

- Mobile - trailer

- Synchronization control panel for 2-16 gensets

- 3 pole/4 pole automatic transfer panel (A.T.S.)

- Fuel and oil heater

- Alternator heater

- Automatic fuel filling system

- Fuel-water seperator filter

- PMG warning system